About Us

Mustad United C.O. AB, founded in 1913 in Sweden, is a decentralized industrial group operating globally across multiple sectors. Each company within the group manages its own operations independently while sharing a commitment to quality, innovation, and sustainability.

Our Values

Quality, Innovation, Sustainability

Mustad United is dedicated to upholding the highest standards of quality and innovation throughout its diverse operations. Sustainability remains a fundamental tenet of our corporate philosophy, driving environmentally responsible manufacturing processes.

Decentralized Governance

We maintain a decentralized organizational structure that entrusts each subsidiary with operational autonomy and accountability. This approach enables agility and responsiveness to local market conditions while ensuring alignment with the group’s overarching commitment to excellence.

Quality, Innovation, Sustainability

Mustad United is dedicated to upholding the highest standards of quality and innovation throughout its diverse operations. Sustainability remains a fundamental tenet of our corporate philosophy, driving environmentally responsible manufacturing processes.

Decentralized Governance

We maintain a decentralized organizational structure that entrusts each subsidiary with operational autonomy and accountability. This approach enables agility and responsiveness to local market conditions while ensuring alignment with the group’s overarching commitment to excellence.

Our story

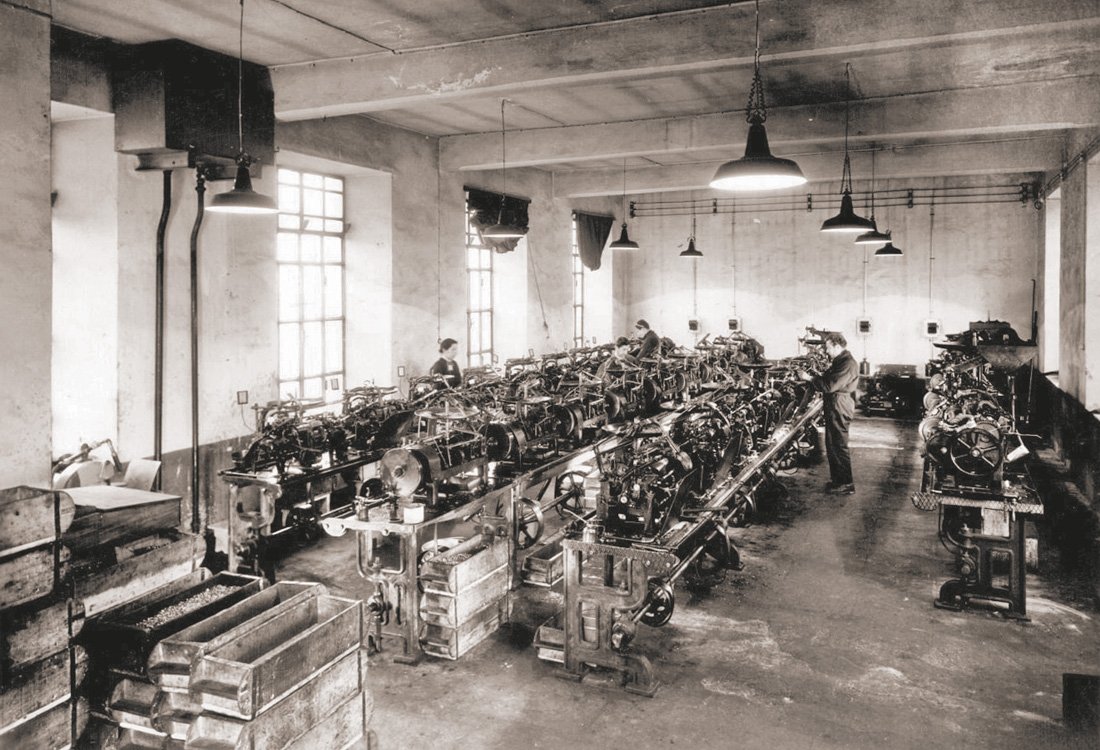

1912: Foundation

The history of Mustad began in 1912, the year in which the Mustad family purchased the company in Pinerolo, in the province of Turin, to manufacture horseshoes nails using a hot forging process. The company was called “O. MUSTAD & FIGLIO”.

1924: The first major development

The horseshoe nail manufacturing process was converted from hot forging to cold forging.

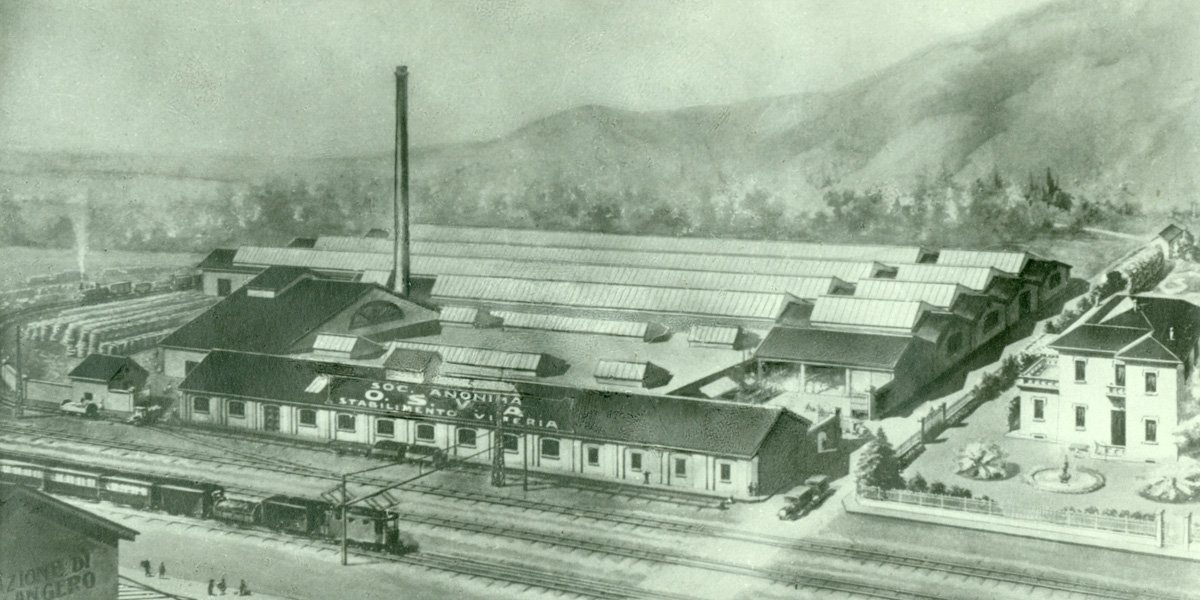

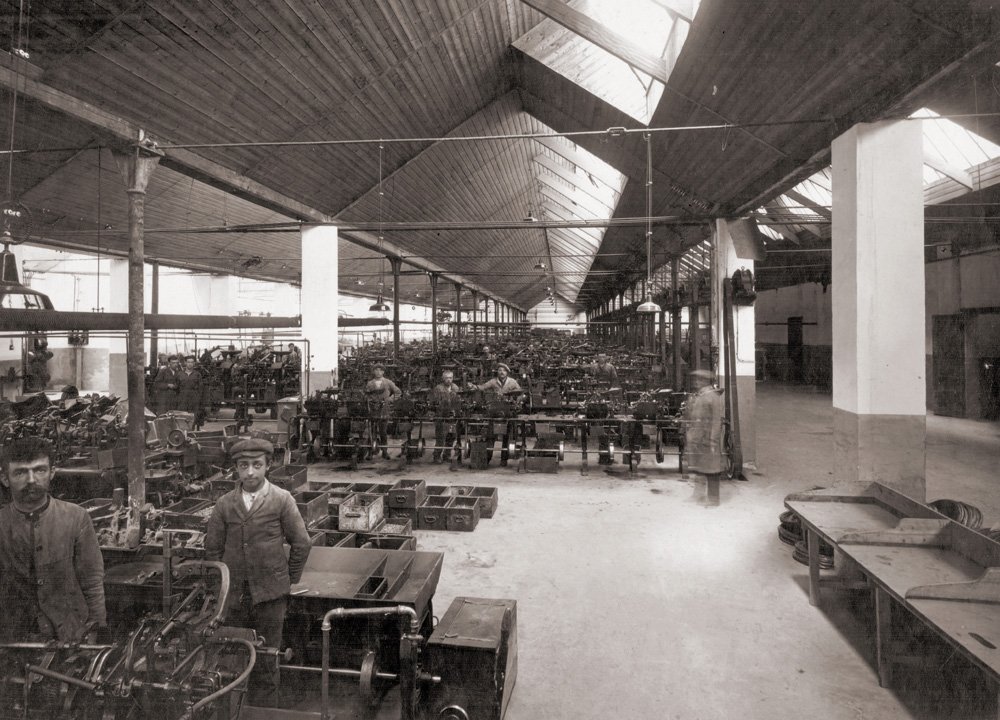

1933: Expansion in Balangero

The production capacity was no longer sufficient to meet the market needs. Another factory was purchased in Balangero, also in the province of Turin, the “Viterie e Trafilerie Riunite”.

1944: The War, destruction and reconstruction

During the Second World War, the Balangero factory was set on fire and destroyed. It was rebuilt in 1947.

1967: The first Case Hardening Treatment furnace

The new self-tapping screws needed a decidedly more complex manufacturing process. The first furnace for Case Hardening Treatment flanked the forging departments.

1976: The manufacture of horseshoes nails was terminated

1977: The first rolling machines

The lathes, used up to this point for threading the screws, were replaced by the more efficient rolling machines, which are capable of producing threads without removing shavings, by using the cold forging technology.

The use of these fast and precise machines enabled the development of the first special screws that industry began to order.

The eighties: The major industrial development

During these years, major investments were made to adapt the manufacturing process and the range of products to the needs of large industrial users.

The better performing screws for chipboard panels, which were heat-treated and could be screwed in using electric screwdrivers, replaced the screws for wood. The Phillips cross head and Pozidriv head replaced the single recessted screw head.

1996: Obtainment of ISO 9000 certification

1997: The manufacture of screws for wood was terminated

2000: A signature on every screw

All screws were “signed” on the head by forging the company logo as a guarantee of quality and origin of the product even after its use.

2003: Obtainment of specific ISO/TS 16949 certification for the Automotive sector

2012: Obtainment of CE marking for the screws for wooden structures

2017: High-performance eco-friendly finishing treatments

The technical development of the finishing treatments was completed to guarantee ever-increasing corrosion resistance and compliance with the constantly evolving environmental laws.

2018: Export

Mustad is one of the biggest European manufacturers of carbonitrided screws. Millions of pieces sold daily to the most important factories and distributors through qualified wholesalers in Italy and Europe.